Product Description

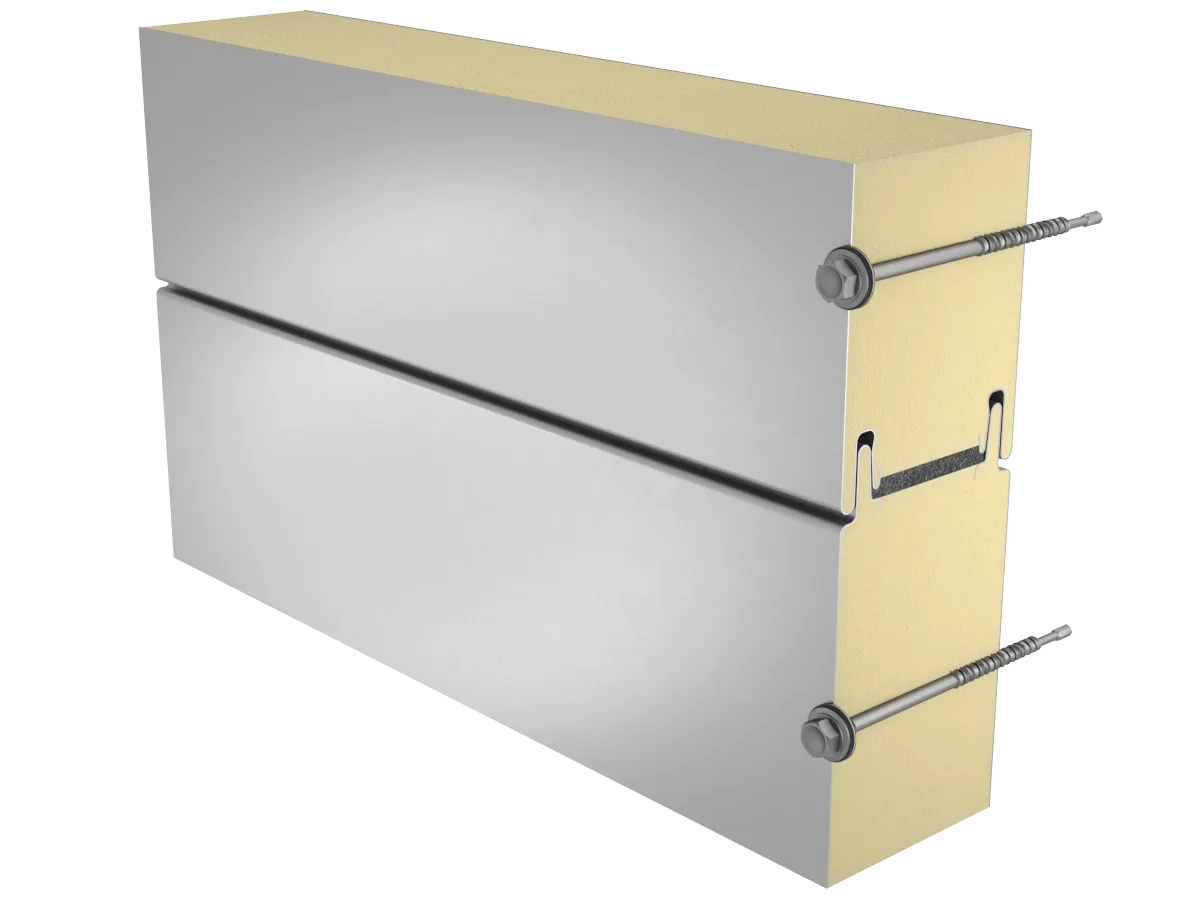

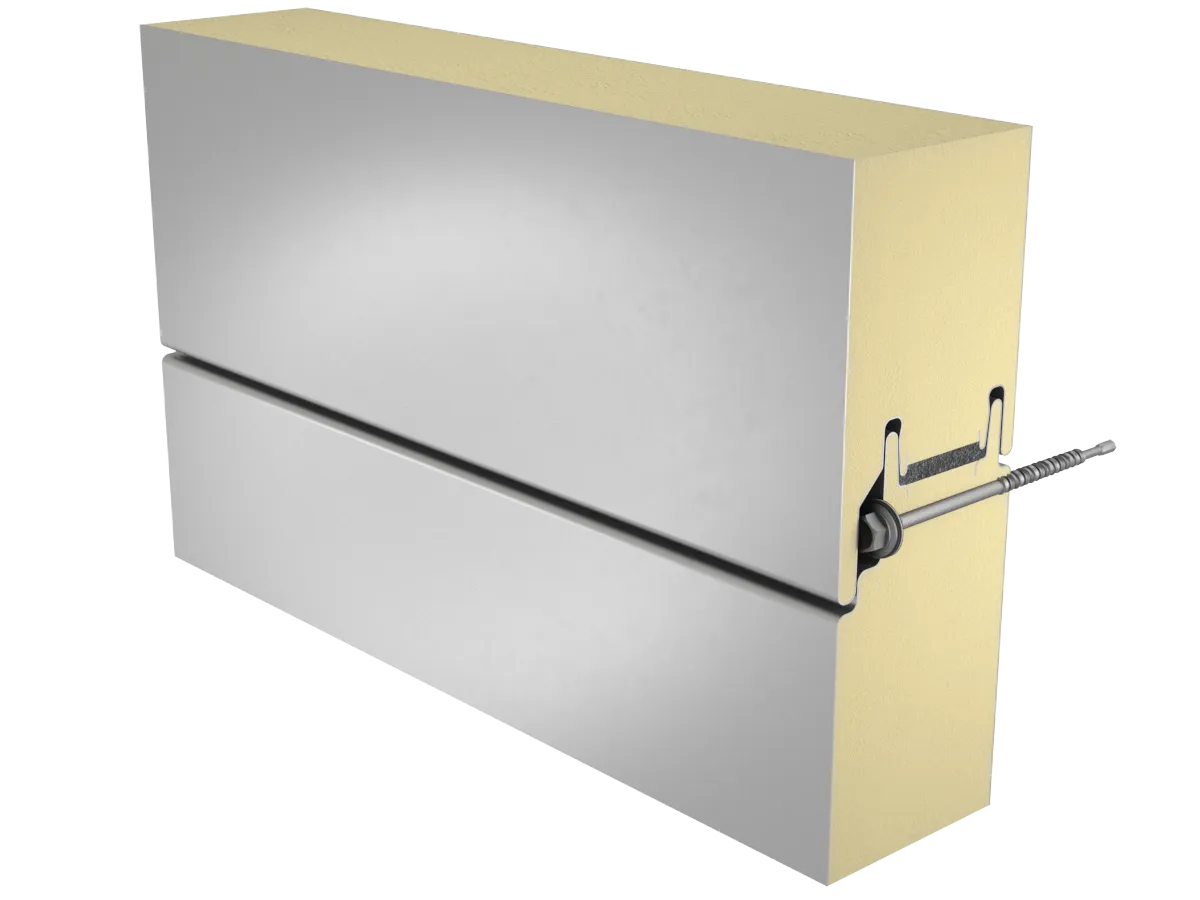

Cladme™ PIR insulated sandwich panels, featuring PIRCore™ technology, deliver unrivaled thermal performance in a slim, lightweight profile. The closed-cell PIR core offers low thermal conductivity, providing excellent insulation values with reduced panel thickness. Available in multiple core thicknesses, these panels achieve impressive U-values. The PIR core also offers good fire performance and dimensional stability, making these panels an ideal choice for energy-efficient buildings with space constraints. Cladme™ offers panels with hidden fixing options with no visible joints for a sleek, seamless appearance and superior dust resistance, ideal for environments requiring stringent cleanliness or modern aesthetics. From planning to installation, our...

Technical Specification

Cladme™ PIR insulated sandwich panels are crafted using state-of-the-art manufacturing processes and premium materials.

Key features include:

- PIRCore™:

- Outstanding thermal insulation

- Good fire performance

- Dimensional stability

- Panel specifications:

- Standard module width: 1150 mm

- Lightweight design

- Environmental considerations:

- Product-specific Environmental Product Declarations (EPDs) available

- HCFC-free, self-extinguishing, sustainable PIR core

Benefits:

- Thinner panels for lower transportation and assembly costs

- Significant savings over the building’s life cycle

This combination of advanced technology and sustainability makes Cladme™ PIR panels a durable and reliable and cost-effective solution for modern construction needs.

| Module width [mm] | 1000 – 1200 | ||||||||||

| Core Thickness [mm] | 40 | 60 | 80 | 100 | 110 | 120 | 140 | 150 | 160 | 180 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fire resistance class acc. to EN 13501-2 | E115 – E160 | ||||||||||

| U [W/m2K] acc. to EN 14509 (2013-12) incl. joint influence | 0.56 | 0.36 | 0.27 | 0.22 | 0.20 | 0.18 | 0.15 | 0.14 | 0.14 | 0.12 | 0.11 |

| Weight [kg/m2] | 10.0 | 10.8 | 11.5 | 12.4 | 12.7 | 13.1 | 13.9 | 14.4 | 14.6 | 15.4 | 16.2 |

| Classification reaction to fire acc. EN 13501-1 | B-s2,d0 / B-s1,d0 | ||||||||||

| Rw [dB] | 24 | ||||||||||

| Max. Available Length [m] | 18.5 | ||||||||||

| Module width [mm] | 1000 | |||

| Core Thickness [mm] | 60 | 80 | 100 | 120 |

|---|---|---|---|---|

| Fire resistance class acc. to EN 13501-2 | EI15 | |||

| U [W/m2K] acc. to EN 14509 (2013-12) incl. joint influence | 0.38 | 0.28 | 0.22 | 0.18 |

| Weight [kg/m2] | 11.2 | 11.9 | 12.7 | 13.4 |

| Classification reaction to fire acc. EN 13501-1 | B-s2,d0 | |||

| Rw [dB] | 24 | |||

| Max. Available Length [m] | 18.5 | |||

Steel sheet thickness

- Internal 0.4/0.5/0.6/0.7

- External 0.4/0.5/0.6/0.7

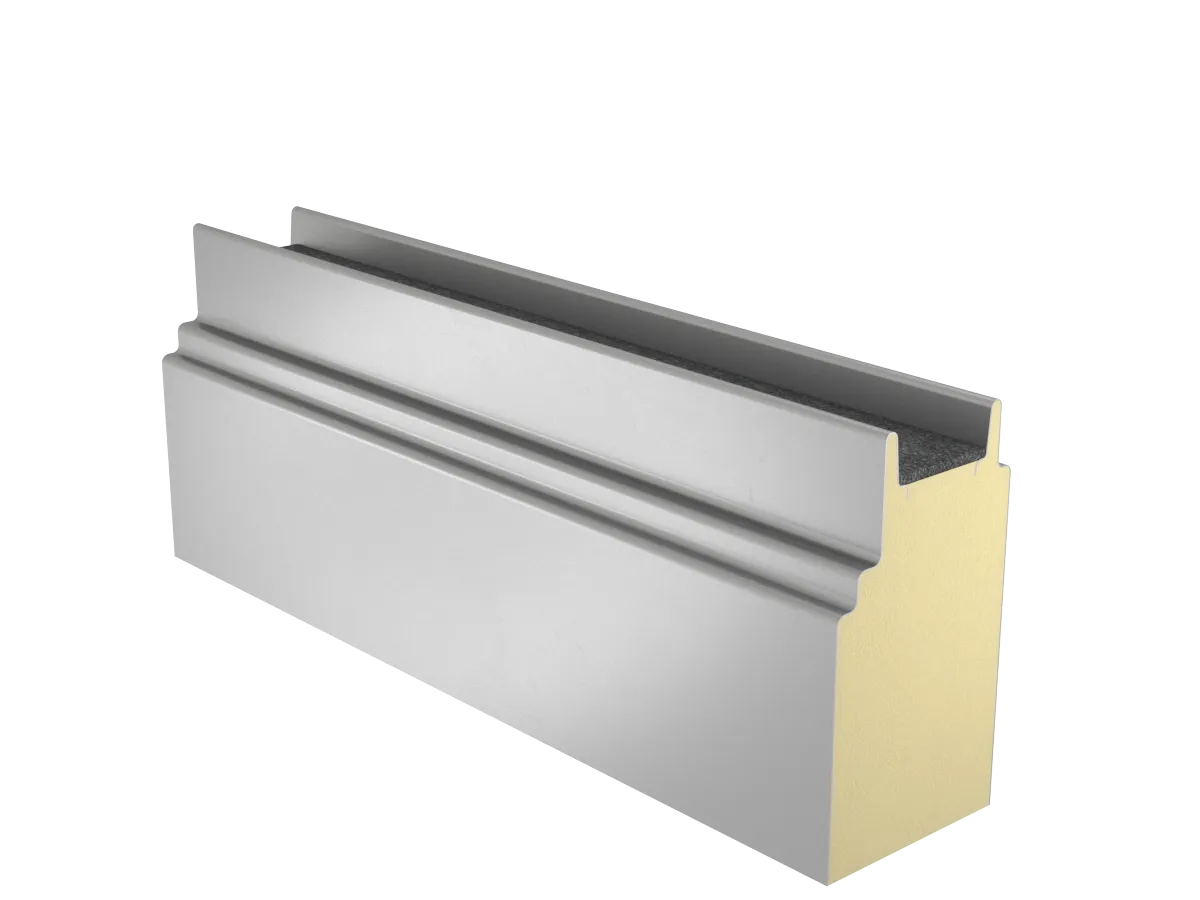

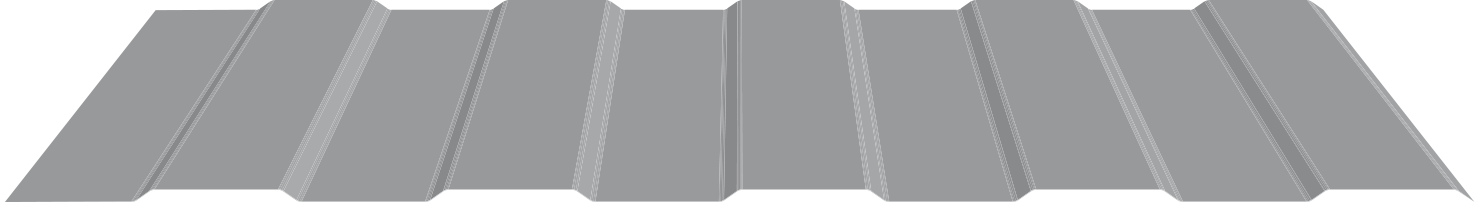

Profile types

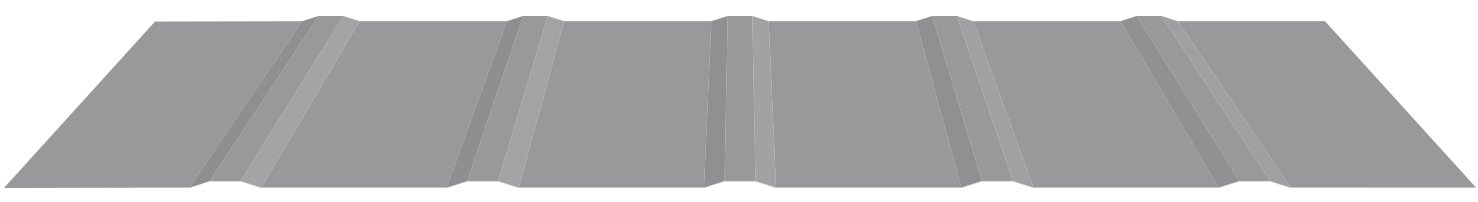

| Profile name | Profiling | External sheet | Internal sheet |

|---|---|---|---|

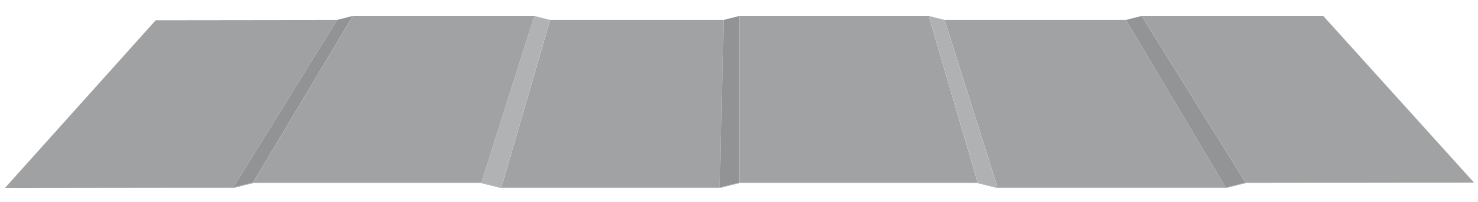

| D (deep) |  |

||

| B (box) |  |

||

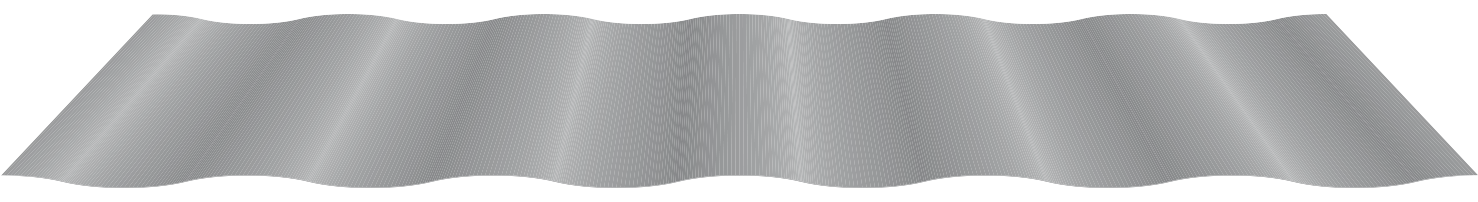

| W (wave) |  |

||

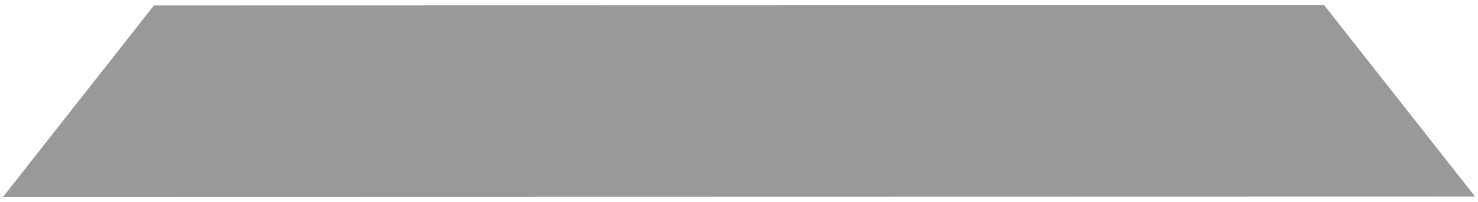

| S (smooth) |  |

||

| M (micro) |  |

||

| L (linear) |  |

||

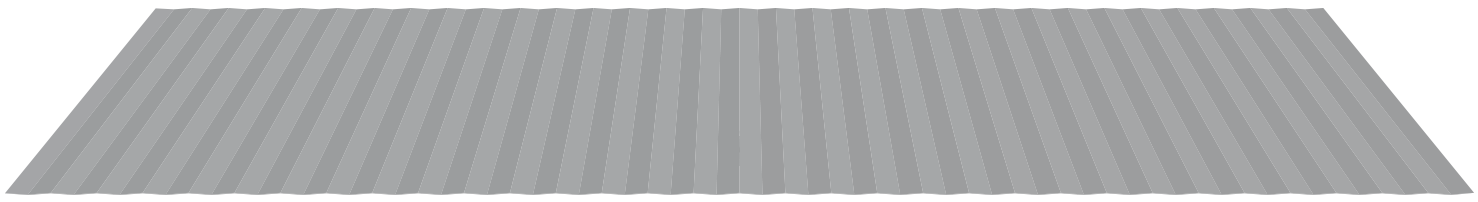

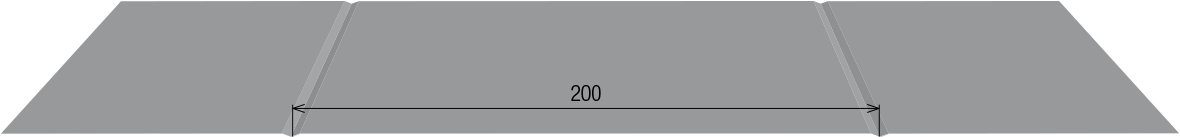

| L (Line 200) |  |

Colours

Golden oak

RAL1015 Light ivory

RAL1021 Colza yellow

RAL2003 Pastel orange

RAL3000 Flame Red

RAL3009 Oxide red

RAL3013 Tomato red

RAL5003 Sapphire blue

RAL5005 Signal blue

RAL5012 Light blue

RAL6011 Reseda green

RAL6018 Yellow green

RAL7015 Slate grey

RAL7016 Anthracite grey

RAL7035 Light Grey

Available for Hidden Fixing

RAL7040 Window grey

RAL9002 Grey White

Available for Hidden Fixing

RAL9003 Signal white

Coatings

- Polyester

- PVDF

- PVC(F)

- Food Safe

- Other

Used in

- Data centers

- Battery plants

- Automotive manufacturing facilities

- Pharmaceutical facilities

- Food Processing facilities

- Agriculture facilities

- Cold storages

- Warehouses

- Distribution centers

- Logistic centers

- Industrial buildings

- Airport terminals

- Aircraft hangars

- Arenas

- Shopping malls

- Supermarkets / Hypermarkets

- Training facilities

- Schools

Benefits

Cladme™ PIR insulated sandwich panels offer exceptional advantages for modern construction projects.

Unmatched thermal insulation performance contributes to superior energy efficiency in buildings.

Lightweight design, compared to mineral wool panels, facilitates easier handling and installation, reducing construction time.

Requires less thickness than mineral wool for the same U-value, reducing transportation needs, container usage, and overall costs.